| In Focus |

Skill up today for a better tomorrow

Skill up today for a better tomorrow

Without sharpening your weapon; standing on the battlefield would not increase your chance of winning, says Ankit Sahay, an author. And, rightly so! Even though the Indian tooling industry

has the determination to compete with its global counterparts, it currently lacks the required trained manpower to help it achieve its goals. Various initiatives and some digital strategies

could come to the rescue and help bridge the skill development gap.

Read More

|

|

|

|

| Leaders Speak

|

India has great potential to grow

owing to its high domestic demand

India has great potential to grow

owing to its high domestic demand

Now, India has the chance to emerge as the new

manufacturing destination as an alternative to China. In

fact, we have a few global companies that have already

invested in India and many more are in the process of doing

so, says - Ravindra Moolya, CEO, Speroni India Pvt. Ltd.

Read More

|

COVID-19 has taught me why it

is important to value manpower COVID-19 has taught me why it

is important to value manpower

I believe when making a decision that could have a

greater impact on everyone, it’s very beneficial to take into

consideration the collective viewpoints of a team, says

- SK Pasha, Managing Partner, Jupiter Tooling.

Read More

|

Tool rooms need to gear up.

Setback ka jawab comeback se dena hai! Tool rooms need to gear up.

Setback ka jawab comeback se dena hai!

The Indian market is set to rebound and will be bigger than

before. But is the Indian tooling industry ready? Each tool

room has to plan for bigger and professional operations.

The defence and aerospace sectors are garnering newer

lucrative opportunities. Tool rooms should consider

exploring such opportunities, says - Sunil Desai, Director,

Designcell CAD-CAM Solutions Pvt. Ltd., and Partner,

SubAero Precision Machining.

Read More

|

The ability to respond flexibly

to the rapidly changing demand

provides an opportunity for

Indian manufacturers The ability to respond flexibly

to the rapidly changing demand

provides an opportunity for

Indian manufacturers

By integrating digitalization and automation, manufacturers

can now quickly turn around ideas and insights into reality,

simulate and validate product performance, define and refine

processes to produce goods within their predefined budgets,

on time and as per the customer’s requirements. This is key to

competitiveness and Siemens Xcelerator portfolio is helping

manufacturers in India achieve it, says - Tony Hemmelgarn,

President and Chief Executive Officer, Siemens Digital

Industries Software.

Read More

|

|

| Tech Focus |

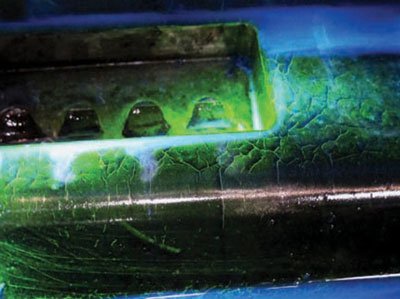

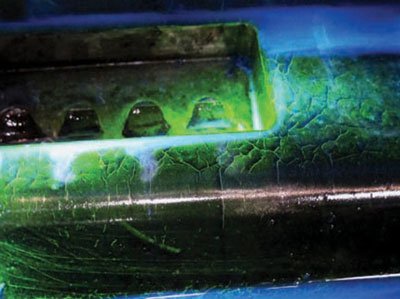

Steel Development for

High-Pressure Die Casting Dies

with Highest Surface Requirements

Steel Development for

High-Pressure Die Casting Dies

with Highest Surface Requirements

Due to technical but also aesthetic reasons

the surface quality of cast products, and of

the die casting dies accordingly, gains more

and more importance. Surface quality is

directly related to the appearance of thermal shock

cracks which are transferred onto the castings during

the casting process. This report describes the new

premium hot-work tool steel CS1 which, due to its

particular combination of properties like unusually

high working hardness, tempering resistance, and

simultaneously high toughness offers an exceptional

resistance against formation and growth of thermal

shock cracks.

Read More

|

|

| Case Study

|

From Die Design to Defect-Free Castings:

Shiva Tool Tech Achieves 80%

Time Reduction with Altair

Inspire Cast

From Die Design to Defect-Free Castings:

Shiva Tool Tech Achieves 80%

Time Reduction with Altair

Inspire Cast

Shiva Tool Tech is an automotive manufacturing

focused, industrial powerhouse based in Pune,

India. With over 25 years of experience in

designing and manufacturing of gravity die casting

(GDC), low-pressure die casting (LPDC), highpressure die casting (HPDC) dies, the company

supports customers at every stage—right from

manufacturing process design to the production

stage. Manufacturing processes include milling,

drilling, hardening, grinding, Computer Numerical

Control (CNC) machining, Electrical Discharge

Machining (EDM), inspection and polishing to get

the final assembly of the casting die.

Read More

|

|

| Industry Updates |

- ABB India opens a new robotics facility to support the digital transformation

of manufacturing in India

- Bosch inaugurates fully automated production lines for protective

face masks in India

- Big opportunity for India to engage with the world and boost exports: CII

- Coming up: Single window system for industrial clearances

- Indian Auto Component Industry clocks turnover of ` 3.49 lakh crore

(USD 49.2 billion), de-grows 11.7 per cent in FY 2019-20

- Sensitive toolholder to monitor machining processes

- Hexagon enhances part loading efficiency with new large volume CMM

Read More

|

|

|

|

|

| Flip Book |

|

|

| Product Update

|

Mould Testing Unit (MTU)

Mould Testing Unit (MTU)

This sturdy & portable unit helps in testing of the cooling

circuits of the mould after the mould manufacturing is

completed and before it goes for the first trials. The tests

that can be carried out with this machine are leakage, flow

rate and high pressure adjustment

Read More

|

|

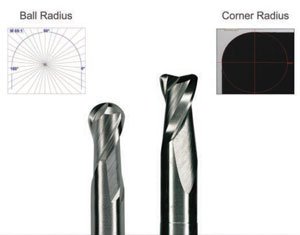

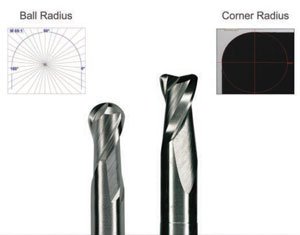

Solid Carbide Endmills Solid Carbide Endmills

Hard part machining require tool geometry with

stable cutting edges and close tolerances.

This Solid Carbide Endmills from AXIS are specially

designed to meet the needs of machining hard parts

Read More

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PDF Copy |

|

|

Skill up today for a better tomorrow

Skill up today for a better tomorrow

India has great potential to grow

owing to its high domestic demand

India has great potential to grow

owing to its high domestic demand

COVID-19 has taught me why it

is important to value manpower

COVID-19 has taught me why it

is important to value manpower

Tool rooms need to gear up.

Setback ka jawab comeback se dena hai!

Tool rooms need to gear up.

Setback ka jawab comeback se dena hai!

The ability to respond flexibly

to the rapidly changing demand

provides an opportunity for

Indian manufacturers

The ability to respond flexibly

to the rapidly changing demand

provides an opportunity for

Indian manufacturers

Steel Development for

High-Pressure Die Casting Dies

with Highest Surface Requirements

Steel Development for

High-Pressure Die Casting Dies

with Highest Surface Requirements

From Die Design to Defect-Free Castings:

Shiva Tool Tech Achieves 80%

Time Reduction with Altair

Inspire Cast

From Die Design to Defect-Free Castings:

Shiva Tool Tech Achieves 80%

Time Reduction with Altair

Inspire Cast

Mould Testing Unit (MTU)

Mould Testing Unit (MTU)

Solid Carbide Endmills

Solid Carbide Endmills