|

|

|

|

|

Volume: XXV / No. 07 |

(Private Circulation For Members Only) |

April - 2019 |

|

|

In Focus

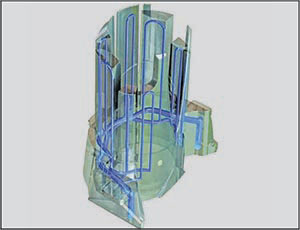

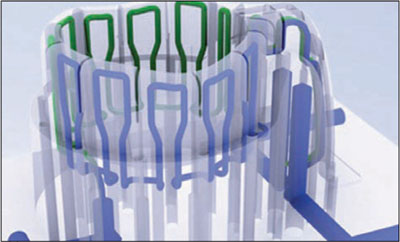

Conformal Cooling:

Need of The Hour

Conformal Cooling is being referred to as the next big thing in the tooling industry. With its’s unique value proposition such as saving time in cooling process and providing uniformity in cooling, it has witnessed an increase in demand. However, building conformal cooling channel is no easy task and it looks like additive manufacturing (AM) is the only option. To find out more, I speak with two industry experts Jayesh M. Rathod, Sr. General Manager & Head, Diecasting Engineering, Godrej Tooling and Arpit Sahu, Director, Objectify Technologies to understand the fundamentals of conformal cooling, benefits of the process, and the future outlook. Read More |

|

Leaders Speak

““OEMs should work closely with tooling suppliers”

“The Indian die mould makers need to be aware that their responsibility doesn’t end on providing a good quality mould. They should also ensure smooth functioning of the mould for the benefit of the end customer. Unless this support is extended, the moulds being supplied will not be viable for the end customer,” says N Prabakaran, Managing Director, DIETECH India (P) Limited.

.Read More

Policy Watch

Safety norms and BS VI transition will drive auto ancillaries revenue growth in FY2020

Higher content per vehicle to support new emission and safety requirement is expected to drive demand for auto ancillaries despite relatively muted auto original equipment manufacturer (OEM) demand. As per ICRA’s note on the auto component industry, the weighted average growth in demand for auto components from OEMs is estimated at 9-10% in FY2019 (as against 9.5% in FY2018) supported by strong commercial vehicle (CV) volumes. The growth for FY2020 is likely to be around 8-9% Y-o-Y. This is taking into consideration the likely automobile volume growth of 8-9% during FY2019 and ~7% during in FY2020, as against 14.5% growth during FY2018 and 5.4% during FY2017.

.Read More

Expert Blog

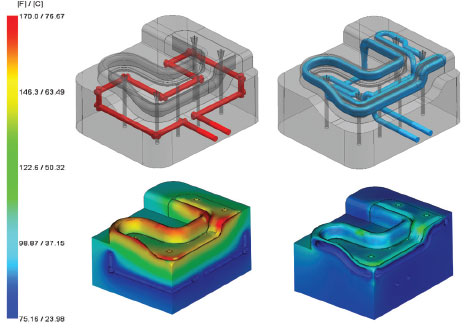

The Emergence of Conformal Cooling

Cooling time in moulds processing takes one of the highest time and directly impact on overall efficiency of the mould. Since the emergence of Conformal Cooling the Mould Designer & Mold Flow Engineer will have flexible ways to design cooling channel. This solution provides opportunity for Mould Designer to think without limiting of hereditary way of manufacturing cooling channels. Read on to know the fundamentals of conformal cooling, its benefits and how it is better option then the conventional ones.

Read More

|

|

Opinion & More

“The future of the Indian tooling Industry is bright”

“There are several factors favoring the Indian Tooling Industry and the biggest is the Government efforts to attract global players to manufacture in India”, says Murlidhar Kadam, Jt Managing Director, TTB Tooling as he discussed about his journey as an entrepreneur, challenges and future prospects in the industry.

Read More |

|

Tech Focus

Don’t Worry, It’s Cool – The Power of Conformal Cooling

In today’s world of plastic injection, there are several factors driving long cycle times. Thermal control of the mold is the most influential aspect. With the inability to evenly cool an injected part, the cycle times run long, warpage is increased and the end product is plagued with tension and stress which often ends with parts failing quality control.

Read More

|

|

Case Study

3D Printed Conformal Cooling Inserts Ready for Prime Time at Bastech

Bastech reduces injection molding cycle times by 22%, eliminates 30-40 hours post-processing time of the molds, and 18% reduction in cost through conformally-cooled, 3d printed, metal injection molds with 3D Systems

Read More |

|

|

Industry Update

- Passenger vehicle sales in India likely to reach 5 million units in FY23

- Royal Enfield to invest Rs 700 crore in 2019-20

- ZF Wins Major Business for New 8-Speed Automatic Transmission

- Bosch’s Two-Wheeler & Powersports Business Unit sees growth in India

- Second half sees subduded growth across all segments of vehicles year ends with mere 5% overall growth

- SIGMASOFT® identifies ideal parts and injection processes virtually

- hyperMILL 2019.2 at Moulding Expo

- CoreTech System Releases Moldex3D R17

2019

- Ashok Leyland bags order for 1290 Buses from Gujarat State Roadways Transport Corporation

Read More

|

|

|

|

|

This email was sent to %%Subs%%by TAGMA India This email was sent to %%Subs%%by TAGMA India

unsubscribe from this list

A-33, NandJyot Industrial Estate Safed Pool, A.K. Road, Mumbai - 400 072 |

|