5th Biennial - Die & Mould India International Exhibition

At Chennai Trade Centre, Chennai From March 3-6, 2006

Inauguration Of DMI 2006

Address Of Welcome Of Mr. S.C. Kalyanpur Chennai.

Distinguished Chief Guest Mr. Viji Santhanam, Colleagues on the Executive Council, Exhibitors from home and abroad, TAGMA Members, esteemed Guests, Ladies and Gentlemen.

I welcome you all with the utmost warmth and cordiality to this the 5th DIEMOULD INDIA INTERNATIONAL event which, to us, is the high season of technology & enterprise.

It is my privilege to specially meet, greet and welcome our Chief Guest Mr. Viji Santhanam whose name is almost synonymous with the growth of the TVS group into a global enterprise. As the Managing Director of Brakes India Ltd. he is known for his vision, enormous vitality, versatile activity and achievements.

This dynamic leadership and guidance has fused the various enterprises in the group into a commonwealth of technologies, education, finance, philanthropy, Trusts, Medicare and myriad other activities. In fact, their number is legion. United in mutual out-look and enterprise, they remain embodied in Mr. Viji Santhanam.

Ladies & gentlemen, welcoming such a one as Mr. Viji Santhanam is a unique privilege for me and on behalf of TAGMA and all who are here, I once again welcome him.

Also, I welcome you all with the same glow to this the 5th DIEMOULD INDIA INTERNATIONAL event.

Ladies & Gentlemen, TAGMA was founded in 1990. The founders drew up a programme of work almost like the five year plan of the Nehruvian era.

The first lustrum was for construction. The second for consolidation. And the third for conquest.

Now, at the end of the third lustrum, it is not without unjustified pride that I look ahead to march with time and people brought together by the great process of globalization which has also brought Mr. Viji Santhanam to us.

New discoveries and technologies are cascading and the time comes to take them by the forelock. It is here that I emphasize the collateral role of some of the government agencies which have to shed their mindset. For years, it had clogged the wheels of development and I trust that the Government will give it a new deal.

With the advent of our fourth lustrum we look to the forward integration that has to take place. Consumerism is peaking. We are talking in terms of volumes and explosive developments. The Tool Room industry is imbued with quality technology, quality time, quality power and quality production. Newer raw materials and alloys have catalyzed the metallurgical sector and the depth and area of their applications is widespread.

Since nothing happens by magic, the Tool Room industry has to get its act together and work to wards making India the future tooling destination. In the process, it must have sustainable advantage, inspire confidence in customers and prove its track record. The vision and mission of TAGMA have been clearly spelt out at many meetings across the country. It is also in the many publications distributed to the industry. They emphasise that no greater mission exists for TAGMA than to enhance the tool room industry in the shinning century before us.

- The industry has the motivation.

- It has the talent.

- It has the technology.

- It has the efficiency.

- It has the capacity.

Thus, Industry growth and the factors of support have to go hand in hand. The fulfillment of yesterday comes today with the anticipation of a globally recognized tomorrow. It beckons us onward. I request you all to move on with TAGMA. It is an institution through which you will grow.

The industry is yet to formulate a central pattern for growth, list its requirements and, in short, prepare a charter of what needs to be done to achieve TAGMA's Vision 2010. I speak from my heart of great hopes and greater expectations and to usher the industry into this aura of global activity.

Ladies and gentlemen, TAGMA hopes to establish link by link the chain activity to cover the industry in the country.

I thank you all for your participation in today's event in such significant numbers.

Once again I welcome our Chief Guest and all of you.

S.C. KALYANPUR

PRESIDENT

Excerpts From Keynote Address Of Mr. Viji Santhanam - Md - Brakes India Ltd. Chennai

- Aims to promote Growth of Tooling lndustry in India

- Forum and catalyst for Technology Advancement in Tooling.

- Market Size - > US$ 6billion Growth > 20% Annually (10-20%)

Tooling Covered

Die Casting & Forging Dies Moulds for Plastics and Press Tools; Guages; Jigs and Fixtures; SPM5 Tool Design; Prototyping; Tool Elements.

More than several 1000 Tool rooms, both Captive and commercial

Customers span whole breath of Engineering Industry

Automotive, Component, Appliances Electrical Industry, Packaging, Teletronics, Consumer goods, Medical devices etc.,

Opportunity for Tremendous Growth

- Indian Economy GDP 7 - 8% last 3 years.

- Finance Minister targeting 12% in Manufacturing Customer Segments of tooling industry.

- Inflation 4 - 5% last 3years inspite of Oil hike and commodity boom.

- FII ($10 billion) & FDI ($37 billion) inflow Sensex 10000.

- Boom in consumer finance and lower interest cost will help domestic demand to grow.

- Industry segments which we wants customers of Tooling Industry - Growth > 20%.

- Lesser Product Life Cycle, More Rapid new products, New Manufacturing Processes Localization - Greater impetus for growth of Tooling Industry. Growth will be a multiple of Engineering Industry growth.

- Scope for growth in Exports - Outsourcing opportunity surging exports demand in your customer Industry Segmore - will manifest as domestic demand for you. Auto -Vehicles components, (Mckensy study on Auto components - Vision-2015).

Challenges

- As per TAGMA - nearly 35% of Tooling Imported my guess may be even higher.

- lmport Tariffs coming down l5 to 12.5% yesterday. Will go down even more, 100% FDI allowed. Customers.

- Will become more demanding on price, Delivery and Quality.

- Delivery Time - fast response 3 weeks to 35 days can be a major competition edge.

- To supply fully tried-out and proven tooling - enhance capability.

- More through understanding of customer's requirements. On line connectivity, 20 to 30 design capability. Simulation software packages. Essential for speed and quality.

- Cluster approach and share of resources - Taiwan example. More optimum utilization of Resources & Investments. TAGMA can playa vital role in this will help on Delivery, Quality and Cost.

- Cost - many cases Taiwan, Still chepaer. Top grade Tool Rooms full-up and higher cost. Customer pressure and lower customers duty will hold to cost pressure.

- Need for good die steels in India - Kalyani Carpenter. But still not enough. Lot still imported. Scope for TAGMA for play a role - Estimate needs.

- Challenge of Technology - Better raw materials, High speed machining, Parametric Design, Standardised Tool elements (Close interaction with customers) 3D modelling and Simulations software, Rapid Prototyping.

Challenge of Skilled people

- Tendency for people to migrate to high paying job and overseas will continue - challenge of retention.

- Invaluable role of Institutes like NTTF, GTTC, CITD, CIPET, lndo-Danish & Indo German Tool Rooms.

- Greater emphasis on Training - institutionalized set up to reduce vulnerability.

- Hallenge of growth - To grab the opportunity - risk taking, investment cluster approach relevance. Growth potential many time higher than GDP on manufacturing.

- Conclusion: India

Inherent advantage

In Tooling very high manpower content - arbitage on highly skilled and managerial manpower (Man power cost > 30-40% on price).

WISH YOU THE VERY BEST AND CONGRATS TO TAGMA.

Press Coverage

Press Coverage Of Inauguration: Growth opportunity ahead for tooling industry.

(Shortening product-cycles call for new designs)

The Indian tooling industry can look forward to years of fast growth and booming demand and at the same time intensified domestic and import competition, according to Viji Santhanam, Managing Director of Brakes India Ltd.

The rapid growth of Industries like automobiles and auto components, domestic appliances, consumer electronics and consumer durables in the wake of rising economic growth and consumer tendency to wards spending would ensure expanding need for dies, tools and gauges. Setting up of production capacity in user industries in India by foreign companies looking for low costs and a large market would add to the demand base for tooling, he said. Also, the ever shortening lifecycle of products resulting from intense competition in user industries and consumer preference for new products would warrant the development of new tooling and designs, Mr. Santhanam said on Friday.

Inauguration DieMould India 2006, the four-day fifth Die and Mould International Exhibition, organised by the Tool and Gauge Manufacturers' Association (TAGMA) at the Chennai Trade Centre, Mr. Santhanam, said the tooling industry would, however, be forced to cut costs as a result of pressures on margins faced by their buyer-industries and competition in Ihe tooling sector both from within the country and imports.

The industry should benchmark its Taiwanese counterpart to develop capabilities for fast delivery and emphasise skill development among the workforce. Otherwise, user industries would be inclined to set up captive tool rooms, he warned.

Skills Base: Mr. Santhanam paid tributes to the role played by institutions and tool rooms the public and private sectors in developing the skill base of the industry. These include the Nettur Technical Training Foundation, Government Tool Room and Training Centre, Indo-Danish Tool Rooms, Indo-German Tool Rooms, CIPET (Central Institute of Plastics Engineering and Technology) and Central Institute of Tool Design.

S.C.Kalyanpur, President of TAGMA, Presided over the inaugural session.

THE HINDU CHENNAI

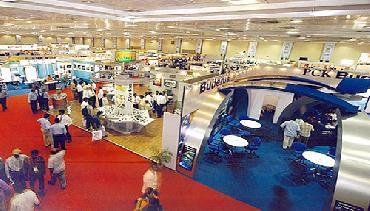

Exhibition

By the Members, of the Members & for the Members

By the Members, of the Members & for the Members