International Tooling Summit 2016

The Importance Of The Tooling Industry

As TAGMA India and the Economic Times present the International Tooling Summit, this is an opportune time to reflect on the importance of the Tooling industry for the Make in India initiative

In recent times, the nation's focus has been on one of Prime Minister Narendra Modi's pet projects, the 'Make in India' initiative. With it, the focus of international manufacturing community is on India and it is thus imperative that the Indian manufacturing sector puts its best foot forward.

The Automobile industry remains a big driver for the Tooling industry, with 65% of all tooling done for this sector. It is thus little surprise to see the demand for automobiles also spur on the Tooling industry. India's dies and moulds sector grew by 6.2% in 2014-15 when compared to the previous fiscal, in the process clocking a value of Rs. 14,647 crores. Of this, the export value of the sector was Rs. 2,869 crores.

While the Indian Tooling industry is consistently growing, India has a very few number of large and foreign-invested Tooling producers while a majority of dies and mould makers operate on a small to medium size of operations. In time, there is much optimism that the industry can again record double digit growth in the years to come, as had been upto 2012.

Over time, the Indian Tooling industry has developed strong design and development capabilities and is now capable of developing tools for a broad spectrum of uses, all of the highest standards. It is thus no surprise to see that Indian companies have started to make their presence felt across Europe and South East Asia. It certainly helps that the Indian Tooling Industry is price competitive, making them perfectly suited to the needs of the export market.

Customers the world over look at cost competitiveness, and the Indian Tooling industry is perfectly poised to meet these demands.

This is not to say that there are no hurdles to overcome. Highly skilled staff are the need of the hour, but they're in short supply and another major issue surrounds the rate at which technology is developing these days. When technology is outdone by newer tech in the short span of 3 years, it leaves a very little window to recover the Return on Investment. Compounding this further is the fact that banks don't provide preferential rates as they would to end users, thus driving up the costs further in what is a cost sensitive industry.

It is critical that we keep in mind the impact that a fast-changing global landscape will have on India, for India must maintain its cost advantage and grow its supporting infrastructure if the manufacturing sector is to make its mark on the world stage. The Tooling Industry is now in a prime position to support and drive this initiative, and with the Index of Industrial Production touching new highs and renewed emphasis on capital investment by the government, the Tooling Industry is all set to witness unprecedented growth in the months and the years to come.

Note from President – TAGMA INDIA

We are a class of manufacturers of Custom Built Tools/Dies for mass production, the Mother Industry of Manufacturing.

Indian Tool, Dies & Mould industry is a B2B business linked to prosperity of the sectors served. Auto Sector being the predominant sector today has a major impact on its growth. The Tooling Industry over the years grew in double digits until 2012 and is now steadily recovering with a single digit at 7% (2014-15).

The Govt. of India since 2012 under its ambitious manufacturing growth policy has initiated a few schemes, our industry happens to be the first recipient of “The scheme Enhancement of Global Competitiveness of Indian Capital Goods Sector’ under DHI -an important milestone and recognition for our association TAGMA- India in its 25th year of formation since 1990.

Tools, Dies and Moulds industry is highly capital intensive being highly sophisticated technology oriented, and hence impacted by issues related to the dynamics of continuously changing technology effecting productivity.

Indian Tooling Industry can meet the ‘Growth Challenges’ coming from present Manufacturing policy if GOI recognize it as a ‘PRIORITY SECTOR’.

Note from Chairman, International Tooling Summit

Tooling Industry ,despite being called the backbone for product development and production, by its inherent nature is very fragmented one and India is no exception. However in advanced countries, they are far more integrated with the OEMs. Now that India has become a center stage for manufacturing, R & D gaining its due focus locally, there is urgent need to collaborate than ever before.

We at TAGMA INDIA the apex tooling association in partnership with ET EDGE, Deloitte and the Tooling Fraternity is having the two days ‘International Tooling Summit’ as one of the prominent Silver Jubilee Celebrations are committed to take forward our industry to the next level of PARTNERSHIP with the OEMs and other partners at this forum.

Post Show Report

The first International Tooling Seminar held on 26th and 27th Feb. 2016 was a massive success with quality participation national and international from the entire tooling fraternity.

The program could be successfully organised owing to support of the sponsors in the various categories

The programme started with National Anthem, followed by Lamp Lighting and inauguration by Mr. Kamal Bali, Managing Director, Volvo Group India; Mr. A Dayanand Reddy- President, TAGMA INDIA; Mr. Wilfried Aulbur, Managing Partner & CEO, Ronald Berger Strategy Consultants-India; Mr. Hidehiko Yamamoto, Specialist-Die Mold Business Development-MAKINO Japan and Ms. Sunita Quadros – Business Head, Times Conference Ltd.

In her opening remarks Ms. Sunita Quadros said, " The strength of tooling industry is directly associated to the growth of auto and electronics business. We, at Economic Times are glad that we could provide a platform which triggers discussions, provides insights and facilitates change and growth of the sector."

Mr. A Dayanand Reddy in his welcome address congratulated the founder members and TAGMA members on the occasion of Silver Jubilee. He said that the vision of 7 founder members and their foresightedness had paved way for the association and since then under leadership of Mr. N Reguraj, Mr. Anil C Kilachand and Mr. Kalyanpur the association had seen high momentum and this teams have put the flag of TAGMA high by their good efforts all along. The activities of the TAGMA are by large focussed on the Objectives in the bye laws like imparting training and knowledge thru NTTF-TAGMA Library, informative publications like TAGMA TIMES, organising Die & Mould India exhibition and various seminars.

He further highlighted various activities/initiatives since the new Executive Council came in power - to keep the flag high and to connect and propagate various activities like

- Shifting of venue of Die & Mould India International Exhibition to Bangalore for international ambience. Also introduction of MSME scheme, loyalty discount and early bird discount;

- Formation of TAGMA Centre of Excellence and Training (a project initiated by the earlier Executive Council)

- International Tooling Summit 2016 a 2 day event : International Tooling Summit 2016 is organised to commemorate Silver Jubilee Year of the association. The Summit will be a technical affair with delegates walking away with good technical insights at the end of the event. The Summit would be an annual event in the years to come.

Tooling industry is a peculiar industry facing challenges like non availability of skilled manpower, iteration rate, high interest rate for term loan and capital high customs duty, with all the bottlenecks we are trying to grow.

Mr. Reddy talked about long term goals of closer collaboration with sister industries. He also requested wholehearted participation from the leading automotive players to help the industry grow. In the light of collaboration, he called for an OEM industries investment of INR 10 Crore as equity for developing a training facility to help small scale industries.

Chief Guest Mr. Kamal Bali, Managing Director, Volvo Group India THE WAY FORWARD FOR THE MOTHER INDUSTRY: What is needed to pole vault the Tooling Industry to the next level in India

Mr. Bali said ‘Tooling industry plays strategic role by ensuring higher value capture in India, competitiveness and building capability of brand India when it comes to manufacturing and is critical and infact correlated with the success of “Make in India’ initiative, therefore it deserves all support from all stakeholders including OEMs, Government and financial institutions and need to be termed as ‘PRIORITY SECTOR LENDING’ which in turn will propel Brand India from being a mere low cost production site to a world class actor on the international stage. Tooling industry should be provided with incentives for new technologies which reduce environmental effect and tax reforms to enable start up some machine tool and die casting especially die mfg. industry.

He highlighted 5 mega trends which will reshape the future i.e.

- Digitalisation - first mega trend

- Shifting of economic powership from West to East.

- Widening economic disparity leading to socioeconomic issues

- Changing relationship between us and our planet

- Pace of urbanisation

China, Germany, Japan, South Korea, USA, Switzerland are the 6 countries exceedingly well in tooling areas. Indian tooling industry is a Rising Star because of untapped potential as 22% of the demand is met thru imports.

He proposed 4 things to take the tooling industry to different level by meeting various challenges like

- Reduce lead times - tool deliveries thru new techniques

- Revup on standards of quality, (aesthetics, durability, repeatability, good fit finish, interchangability of components)

- Safe and Environment friendly methods, materials and processes

- Diversify into other emerging industries (4 other emerging industries like railways, defence, aviation, ICET by investment in technologies and new skills)

He stressed that there should be regular interface between OEM and the tooling industry in the following ways.

- Tooling industry start looking at good tool design capabilities, participation in concurrent engineering with OEMs; get involved with OEMs at the design stage rather in later stage for making moulds, design optimise and tooling friendly components; work with target costing, be innovative; focus on skill development skills of today may not be relevant tomorrow.

- OEM industry can in turn be partner for developing tooling suppliers, and also provide financial support on pragmatic basis

Next 5 years you should be let alone please do not govern us give us a level playing field, be enablers instead of being regulators.

He congratulated the organisers to get all stakeholders together especially when there is lot of urgency, ranker and seriousness about Make in India campaign and wished the summit a huge success.

Keynote Address by Dr. Wilfried Aulbur, Managing Partner & CEO, Ronald Berger Strategy Consultants-India : Making India the manufacturing HUB of the world - Needs a vibrant, robust, sustainable growth of Indian Tooling Industry

Dr. Wilfried Aulbur talked about steps towards making India the global manufacturing hub. He stressed the need to focus on quality and making Indian products equivalent to import standards. It can be achieved by frugal engineering, regular quality assessments, solution and application engineering, timely delivery, project management, incorporation of customer feedback and adoption of best in class practices.

Dr. Aulbur discussed the Impact the Tooling companies will have for Make in India. Indian Tooling Industry is doing well and things are moving upwards however the tooling manufacturers have to attain the Fit and finish of the global standards. Our tools should meet much enhanced tolerances and quality. Our level of capability should be at par with global level. The automotive industry is not the play of OEMs or tier1 a supplier but of the eco system down to the last chain in this ecosystem. Quality performance and capability in terms of technology development and partnering with OEMS is not only opportunity but challenge.

India will be the 3rd largest passenger car market

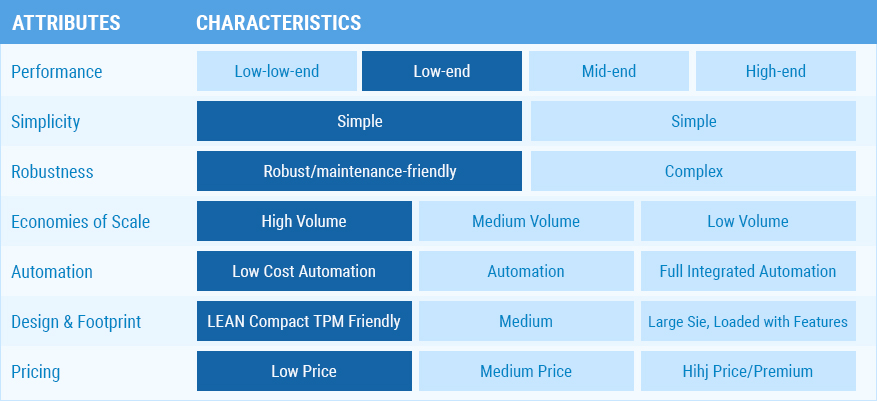

Customers today are more demanding and increasingly desire complete solutions from Indian Toolings & Machine tool suppliers like- Low cost automation

Solution to specific needs. Better commitment, automation of existing equipment, Standard machine elements to be used; Variety of solutions, Pick & place, loading unloading system, Auto Counting Lower running cost, high uptime, Low changeover time, High MTBF & low MTTR - Testing, Inspection & Validation Equipment

Working solution for products in market, Increase number of suppliers High precision testing& inspection, high level of repeatability & reliability, lower lead time, vision based systems Accreditation from globally recognized institutions, Practical training program for Critical parts Handling, Operating and Validating - Assembly lines automation

Optimized solution, time line to be followed effectively

Line design should be lean and use best cost technology devices, single piece flow

Low cost, low cycle time, High MTBF & low MTTR - Tooling

Single window solution expected, Custom made & quality toolings, Increase number of suppliers

Low cost & meet tool life same as imported tool

Fast tools change over , Avoid human error on tools change over - Jigs & Fixtures

Customized solutions to be provided, design & precise machining

Enhance design reliability, chip flow & workmanship

- Technology

- Solution and application engineering, machine design

- Reliability, breakdowns, sub-systems, peripherals and other issues

- Build quality, aesthetics, size and footprint

- Delivery and project management

- Commissioning, first time plug/play, documentation, training

- Incorporation of customer feedback, lack of sharing proactive improvement

- Cost

Indian machines are cost effective when in comes to initial purchase price; for standard applications – cost is almost 20%-30% cheaper

Foreign players are lowering prices - Spares/ Service

Availability of spares an issue with imported machines; some manufacturers provide on-site spares storage

Domestic machine tool manufacturers have built up extensive service network as competitive advantage - Flexibility & CRM

Flexibility of Indian machine tool players is a key advantage

CRM feedback is mixed – some said excellent, some ranked imported suppliers better

- Proactive Management of Supplier Base

- Standard Levers to Cut Cost of Materials

- Integrated, Flexible Value Chain

- Leveraging The Supplier Network

- Casting components

- Tools, Fixtures and gauges

- Simulation and Modelling

- Validation Engineering

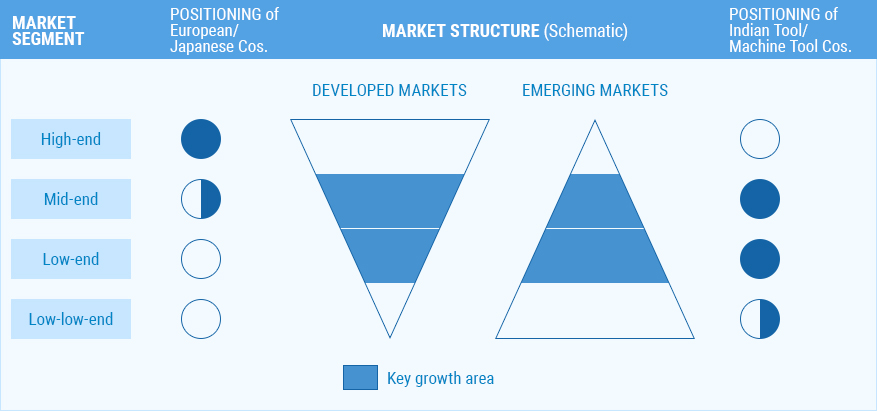

"Smart Frugal Indian Tool" positioning can allow Indian industry to meet growth aspirations by understanding customer needs

Indian Toolings & MT players should become strong players in low-mid segment with high quality, cost-effective solutions

The summit had 2 panel discussions with moderation from Deloitte the summit knowledge partner

A leap towards a long term growth of the tooling industry in collaboration with automotive sector

Prabhakar Kadapa, CEO & MD, AVTEC

Wilfried Aulbur, Managing Partner India, Ronald Berger Strategy Consultants

Anoop Chaturvedi, Vice President-Production Engg, Maruti

Marya Corum, Director -Cosma International

Moderator : Kumar Kandaswami, Partner-Manufacturing, Deloitte India

Challenges Ahead for the Tooling Industry

Sanjiv Paul, Head-Manufacturing, Yamaha India

Dr Mohan Godse, Executive VP-Product Development, Endurance Technologies

Vijay V Deshmukh, Ex-VP-Engineered Tooling Solutions, Larsen & Toubro

Vijay Pratap Singh, Head-Motion Control Business, Siemens

Moderator : Easwaran Subramanian, Partner-Supply Chain & Manufacturing Operations, Deloitte India.

While it was echoed that there is a great potential for the tooling industry, the speakers/ panelist believed that there are quite a few challenges the industry should over come to achieve double digit sustainable growth. Some of the key challenges mentioned included reducing lead time at OEMs, skill deficit, talent retention and quality of indigenous projects.

With OEMs churning new products at an increased pace to keep up with fast changing customer demand, the expectation from Tooling industry is to match the pace. Also, it was noted that there is a huge skill deficit in the tooling industry when compared to the market outside India. Additionally, since the industry is very fragmented with no large players and low capital inflow, employee retention is a challenge. The prime reason for relying on imports indicated by OEMs was superior quality pointing at the lack of innovation and low adoption of technology in the Indian tooling industry.

Other challenges included shop floor safety & adoption of environment friendly practices and the ability to diversify to cater to other industries such as Defense, Aerospace etc. Participating members in the summit agreed to the need of organizing manufacturing trainings and workshops for smaller tooling companies with support from automotive OEMs. A collaborative approach with OEMs and doing right the first time itself was cited as the way forward to achieve reduced delivery times.

After panel discussions a number of global experts from tooling & gauging industry made technical presentations around the changing technology landscape in the industry.

Key technologies discussed on the first day were

The evening session kick started with Motivational speech by Smt. Jaya Row who narrated on Vedanta. Industry presence was complemented with government representation from Central and State Government. They showed interest in uplifting the tooling Industry and pledged support through various policies for enablement of the growth needs.

The Silver Jubilee celebration started with a round of felicitation and recognitions.

Founder members

Past EC members (for their contribution to TAGMA.)

Tooling Industry stalwarts for their contribution to the Industry

The entire felicitation function brought and the various narrations the glorious and other moments in the 25 years joining of TAGMA INDIA since founding. The session ended with the announcement of the evenings Gala Dinner with the guest and delegates busy building up network and fellowship amongst the fraternity present.

Day 2

The day 2 started with Welcome Address by Mr. L Krishnan, MD, Taegu Tec India followed by opening address by Mr. A S Raju - Senior Vice President-Supply Chain, Maruti Suzuki India Ltd.

The day had many engaging technical presentations from global specialists on trends, challenges, capabilities and innovation in Tool & Gauge industry.

The summit concluded with a note from Senior TAGMA EC Member, Mr. D K Sharma (Chairman International Tooling Summit) thanking the organizing team and all attendees. He called out for a better integration among ecosystem players and organization of similar events more frequently, where everyone can come together to strengthen the tooling industry.

By the Members, of the Members & for the Members

By the Members, of the Members & for the Members