The seed for the above event has been done around two and half years back, in the month of Dec 2014. On 13th Dec 2014 TAGMA invited the entire tooling fraternity, buyers covering OEM’s Tier 1 and Tier 2 suppliers, valuable client from Auto Industry and others in Pune and adjoining region to plan the way ahead Special Purpose Vehicle (SPV) i.e. TAGMA Centre of Excellence and Training and to connect the buyer network with the supply chain network as per the requirement of the DHI to run the Public Private Partnership model.

During this meeting Mr Manoj Patil, Head of Department of Supplier Readiness Management, Corporate Purchasing of VOLKSWAGEN, Chakan Plant, India was present and spoke about the importance of tooling industry and he wants more Indian tool makers involved in the automotive industry to improve the local content and to incorporate high technology. The same topics were discussed during the International Tooling Summit along with Executive Council of TAGMA.

Mr Rohit Thawani, existing customer of Volkswagen and co-opted Executive Council member of TAGMA India was in continuous contact with Supplier Readiness Management team. He invited Volkswagen to participate in equity of TAGMA CET. Since May 2017 we had serious meeting with Volkswagen team the modality to involve the Indian toolmakers.

The date was finalized and communication started through TAGMA Secretariat to TAGMA members. The mode of selection of the suppliers inviting to the tech show was purely the decision of Volkswagen management and TAGMA facilitated the activities to make it successful.

Volkswagen India Supplier Readiness Management (SRM) team organized a “Technical show of Indian Toolmakers at Volkswagen Pune plant along with TAGMA (Tool and Gauge Manufacturers Association of India) on 31st Aug 2017. The event was primarily an exhibition exercise of ‘Toolmakers from India’ to showcase their capabilities, technologies and product portfolio. The event aimed at understanding the capacity of Indian toolmakers in terms of the challenges and opportunities encountered by them. It also offered them a platform to directly interact with purchasing, engineering, and quality teams at Volkswagen India.

The Agenda of the event :

The event started with welcome speech by Mr Dinkar Patil, Manager – SRM, followed by briefing of safety protocol by Mr Suresh Chowdhury.

The event inaugurated by lighting the lamps by Mr Steffen Heim, Mr Kasparek, Dr.Plagens, Mr Pravin Akarte, Mr Sachin Kulkrani, Mr Manoj Patil, Mr A Dayanand Reddy and Mr R Sree Prakash.

During opening address Mr. Heim, introduced VW group through Video presentation. He was impressed with the engagement of the toolmakers in the event and that is what VW looking for, and the entry lobby is converted like a big exhibition. He also presented upcoming projects, and mentioned that 55% of project cost is from Tooling & Equipment’s and here Indian Toolmakers can contribute..

Mr. Reddy thanked VW for giving this wonderful opportunity for Indian toolmakers. On behalf of our entire association a big thanks to Mr Heim and Team for their hospitality and the level of involvement displayed by the team in holding the landmark event – technical show of Indian toolmakers.

"Diverse India, multi-cultural and multi-lingual, with average age of the population at 27.6 years, whereas Germany at 47 years, a big room for growth. The density of cars (number of cars / 1000 inhabitants) in India is 32 and in Germany 549.

Mr Steffen Heim,

Executive Director, Corporate Purchasing – Volkswagen India

“The event was first of its kind for the Indian toolmakers at the OEM place and it has installed a lot of enthusiasm and optimism in each of us”.

Mr. A Dayanand Reddy

– President, TAGMA India

Mr Kasparek, Head of quality Assurance - Volkswagen India, Economy Car what we are planning to do is to improve the cost, which is to simplify the high specification. Tool makers play a major role in quality, may be most important one, not only for quality and also for the price. Nobody talks about the toolmaker, everybody talks about TIER 1, TIER 2, may be you are more important and set the base, correction if any at the initial stage to avoid quality issue, or recall at later stage. We seek co-operation with you and we always not be the nice guy, we will challenge you and I hope that the mind set and pride in the team will be there in achieving the tool quality.

Mr Manoj Patil, Head of SRM, Corporate Purchasing of VOLKSWAGEN, Chakan Plant, India shared his objective - identify capabilities and capacity of Indian Toolmakers. Expand Indian toolmakers base, use of more Indian toolmakers base. Optimise tooling investment for VW future projects. Explore small tools export possibility to VW brands from Indian toolmakers. SRM follows seven gate approach for smooth ramp up of production phase and as well throughout life cycle of the product. We work towards the goal of prevention. Metal and powertrain, 60% of tools developed outside India and plastics 75% of tools developed outside India. High potential to make these in India.

Shared success story of armrest with fabric insert moulded plastic part, which required specific technology knowhow. Collectively decided to develop the tool with TIER 1, Captive toolroom ie CTML Chennai. Cross functional team had workshop and lesson learnt shared with existing similar tool, done the deep analysis and developed the working plan for execution. Impressive result with first sample approved to print ahead of the schedule. In another part development we found that the capacity was not available and the cost of the tool was higher than imported from Korea / China. Some of the capable toolmakers was not in the list of approved list of supplier, so lost the opportunity.

Some of the observed concerns are limited capacity, limited capability, missing high tech – like use of five axis machines, missing specialization, ‘my tool is okay’ approach, mind set of itna to chalta hai, more time for optimization process and limited product understanding. Shared some of the concerns, and areas for improvement. Work on the standardize way, reduce the lead time, improvement in accountability, transparency and ownership and it should reflect in day to day work. Cultivate first time right approach, with concurrent engineering and best class project management with culture of improvement in communication.

Mr Rohit Thawani, co-opted Executive Council member of TAGMA India presented capability and capacity improvement opportunity and make in India concept for tool makers in and around Pune through TAGMA CET (TAGMA Centre of Excellence and Training). He invited to visit the centre at the end of session. Government of India, through DHI sponsored 80% of the machine cost which is at 26.27 crores INR , to improve the capability and reduce the dependency on exports and partly to support the capacity in the region. TAGMA believes that manufacture in India to be succeed tools have to be made in India. He invited to participate in the equity of TAGMA CET which is now critical for the project. Based on the survey, the machines required for the centre is shortlisted. The centre will provide try-out services, machining services, Training and skill development, design services and expert intervention and match making. Invited the buyers to identify the potential toolmakers, take a calculated risk, share the knowledge – lower the risk, think long term and make more tools in India. The more you know about the tool and tool making, the risk will be lower. Create a partnership of win-win.

In the technical presentation with topic “New technologies & potential investment in tooling Industry” , representing plastic commodity – Mr. R Sree Prakash, Vice President of TAGMA India, presented on behalf of Mr Nagendrappa Pujari, EC member, TAGMA India. In-line with Mr Manoj Patil’s as mentioned in his speech about the objectives, expectations, concerns and area of improvement – Buyers expectations are having tooling solutions with Product design optimization for tooling, tool cost reduction, tool lead time reduction, running and maintenance cost reduction, quality product, longer tool life, lower cycle time and many more. How to meet these buyers expectation as every task is linked to product design. Early engagement of tool makers and nominate the tool makers to be on board on every stage of design and this gives tremendous high value result – a concurrent engineering. Involvement of the product designer along with quality assurance department in the qualification of the parts will leads in better project management.

Continuing with same topic, representing metal commodity - Mr Yogesh Gupta, Nagata India, presented on behalf of Mittul Soni, Managing Director of Nagata India. The passenger vehicle volume from current 3.7 million to 7.3 million by year 2027, a market growth 2 to 2.5 times, there is a huge potential. Localized sheet metal tooling in India is about 26% and 74% imported. Cost is favourable to make in India, on time delivery is challenge, lowered lead time, better project management, ease of ECN management, ease of die maintenance and better control on quality assurance and thus there is scope for localization. The factors delaying the localization within India were explained. The comfort level from existing overseas toolmaker, mind-set of OEM and tier 1 need to be changed, historically India is not a tooling country notion need to be changed. Business feasibility of commercial tool making is a challenge. Toolmakers skill set and tier 2 and 3 eco-system of vendor base is another challenge. Project management capability as a toolmaker is one of essential key factor to make on time delivery. Concurrent engineering is also important. Similar lesson learnt or sharing the process, share to understand the previous technical learning will reduce the risk and improve the success rate. Visibility of upcoming business / models information sharing with suppliers will helps in adding the required resources. Toolmakers are using the high end software similar to overseas supplier like formability testing, interference testing, and surface modelling through soft engineering to improve the quality and lead time.

One of the real case study is shared is Tailor Welded Blank (TWB) technology, by definition a tailored blank is a sheet of steel that combines several grades and/or various thickness and/or different coatings. TWB have clear advantage of increase the technical performance without increasing the weight. Reduction of the weight of monolithic part by maintaining the same technical performance.Simplification of the manufacturing process. Nagata India is exporting the dies to Japan, Indonesia, Mexico and Europe.

Mr Marc Weinmann, Owner and CEO of VEM Toolings, shared his experience of sourcing tooling in China and met more than 100 tool makers in Shenzen area in the year 2000 and not happy with outcome with quality of tools and after three years of struggle decided to make own tools and thus VEM tooling is born. Due to broad customer base and broad industry base, survived in the year 2007-2009. Since 2007 made many trips to India – Chennai and Mumbai, finally in the year 2016 started tooling operation in Pune – India. China exported the moulds more than what it imports, there are about 50,000 toolmakers in China and around 20,000 in Pearl River Delta. One child policy may create a dark cloud in the future, may be no workers.

Shared what he observed in India. Many small shops with 5-30 staff, they know internal cost very well, price stability, most of them speak in English, good analytical and engineering skill. Lot of good toolmakers are coming up. Hats of the presentation done by Mr Rohit Thawani, clearly mentioning the problems faced by the tooling industry. VEM have 10 dedicated sales person mainly in North America, Mexico and Germany. Before VEM start quoting we will have clear understanding of payment terms, commitment to get down payment to support the high capital Industry and to pay the staff and suppliers on time. If payment terms are not supporting – we will not take that piece of business. Small supporting Industry for tool making need to develop. In India, there is clear indication of improvement and next watch out will be the technology changes like instead of removing the material – add material.

Inauguration of Exhibition

The exhibition inauguration done by cutting the tape. The dignitaries from the left to right are Mr Sree Prakash, Mr Pravin Akarte, Mr Steffen Heim, Mr Dayanand Reddy, Mr Kasparek, Dr.Plagens and Mr Sachin Kulkarni.

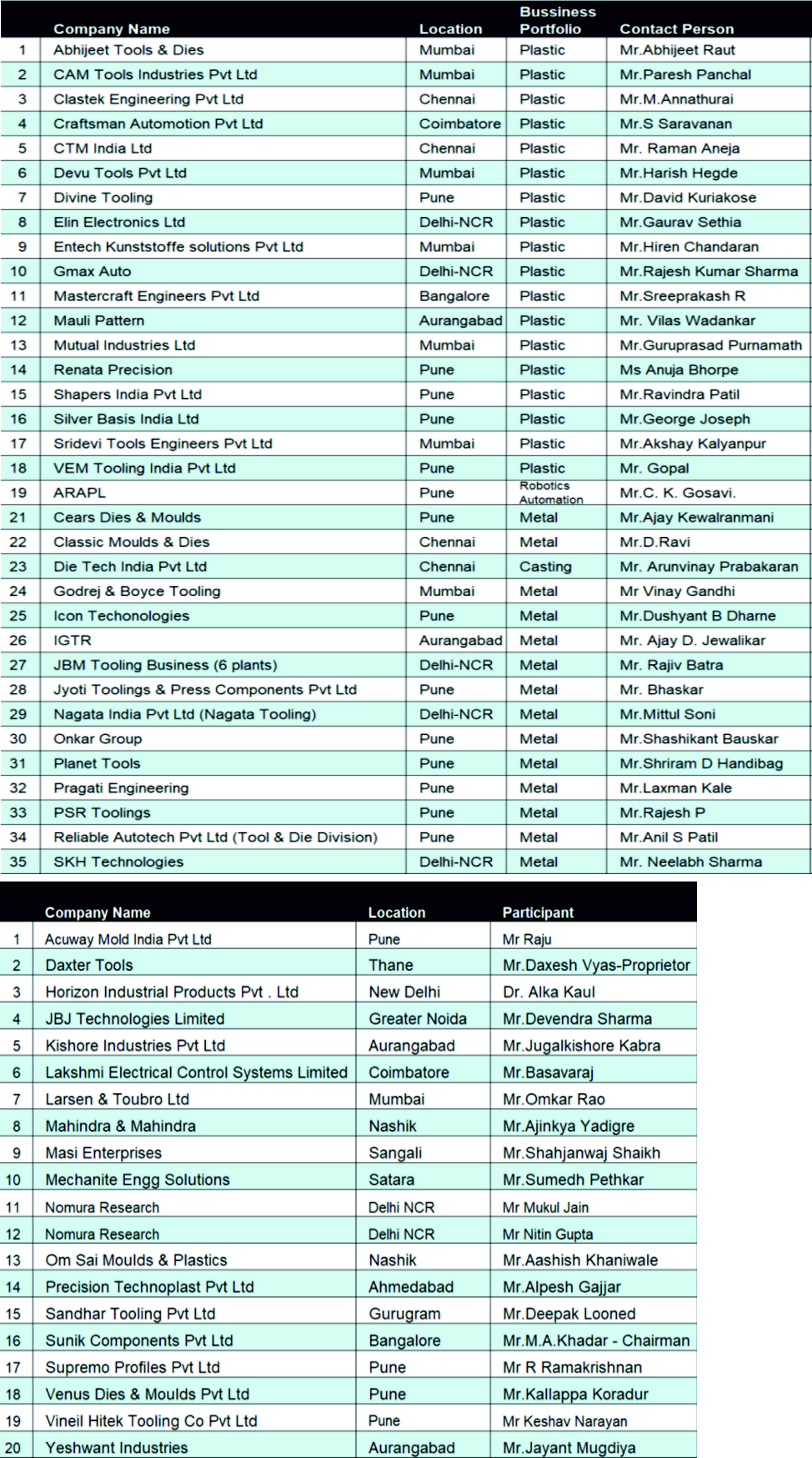

34 exhibitors from plastics, metal and die-casting area attended the event along with Executive Council members of TAGMA. Purchase colleagues from MAN and SCANIA were also present at the exhibition. The information displayed in the exhibition stall was standardized. The hardcopy of participant’s directory is released during the event and copy is given to all for future reference.

20 non-exhibitors attended the whole day event.

The event participation certification is given to all 34 participants by dignitaries of Volkswagen and TAGMA.

Mr Pravin Akarte, Head of New Product Launches, Volkswagen concluded the exhibition by stating the future potential advantages of the partners working with “Make in India Toolmakers”. The participants were all excited about the daylong event and shared their feedback towards the end of the day.

Mr. Paresh Panchal – MD of Cam Tools, Mumbai “ We appreciate the unique platform provided by Volkswagen for the Indian Toolmakers. It feels great to have displayed our tools and got a chance to interact various teams at the plant”.

Mr Raman Aneja – Head of Toolroom, CTML Chennai “The event was very well organized despite the fact that toolmakers are the last in the supply chain. We got an opportunity to visit the plant and directly understand the expectations of the customers”.

Mr Sachin Mohan Kulkarni, the lead organizer of the event and SRM Manager, Volkswagen gave vote of thanks. Convey thanks to all exhibitors, participants, TAGMA Executive Council members, Volkswagen group management, SRM team members, Safety & Security team, Administrative department staff and event management team from Absolute Concepts for making this event grand success.

Special thanks goes to Mr Manoj Patil, Mr Sachin Mohan Kulkarni and Mr Dinkar Patil who conceptualize the event from start to today’s status. And as mentioned by Mr Paravin Akarte, this will continue and shall make use of the Indian tool makers base in future car models from the beginning of the program, as a part of concurrent engineering.

“The team as a whole is better and smarter than the sum of the individuals “ - is proven in this event. Excellent team work demonstrated by Volkswagen, TAGMA and Tooling fraternity.

By the Members, of the Members & for the Members

By the Members, of the Members & for the Members