The Tool Room Industry form an integral part of the production process in almost every industry and are considered the mother industry of all manufacturing units in the country. The rapid growth of industries such as Automobiles and Auto Components, Domestic appliances, Consumer Electronics and Consumer Durables – in the wake of the rising economic growth – ensures the expanding need and demand for Dies, Moulds, Tools and Gauges. The ever-shortening life-cycle of products, resulting from intense competition in industries, also warrants the development of new tooling devices and designs.

Earlier the tooling industry was dependent on automobile and auto component sector for majority of its business but today sectors like White goods, FMCG, Electrical switchgear and PVC fittings are also contributing to the growth of the Indian tool making industry. The Government’s focus on ‘Make In India’ campaign and emphasis is being given to the emerging areas like Aerospace, Defence, Power, railways and heavy engineering has given a new lease of life to the tooling sector with an expectancy of 15-20% year on year growth. The campaign has also captivated the collective consciousness, and the Tool and Gauge manufacturing industry will need to play a pivotal role in making this vision into a reality. However, despite the various other policies that form an incentive for the tooling industry, the sector is yet to make a mark in the global picture.

After demonetization, manufacturing sector was expecting considerable measures to boost the economy and the recently presented Union Budget 2017 comes across as a well balanced approach as there are many important proposals which will have positive impact on the manufacturing industry. Higher allocation to infrastructure, railways, housing, airways, defence, shipping etc will spur manufacturing activity in the country. Similarly, reduction in corporate tax rates to 25% for entities with turnover less than INR 50 crores will boost SME sector. In the Budget 2017, the Government has also removed the inverted duty structure in industries like LED which will give a great boost to the manufacturing sector.

The second edition of International Tooling Summit 2017 held on 9th and 10th February 2017 at The Grand New Delhi is one of the TAGMA’s endeavour and commitment to the Indian Tooling Industry a platform to present to the world, their state of the art technology, and qualitative products despite the lower cost of operations and provide networking opportunity. The Summit aimed at Driving the Indian Tooling Industry for Self Sufficiency.

The two day summit brought together 300+ key policy makers, CEOs, MDs, manufacturing heads, purchase heads, business heads, etc. under one common platform, to discuss best practices and seek solutions to some of the most pressing challenges in the manufacturing industry. The Die, Moulds and Press Tool manufacturing industry has substantial multiplier effect on the domestic economy hence must be nurtured to become self-reliant.

The programme started with National Anthem, followed by light lamping and inauguration by the Chief Guest Rajiv Gandhi - Executive Director, Production, Maruti Suzuki India Ltd; Guest of honour S K Arya - Chairman, JBM Group; Keynote Speaker Michael Walter - Managing Director, Buderus Edelstahl GmbH, Germany alongwith dignitaries Mr. Rajeev Wasan – Senior Vice President, Honda Cars India Limited; Mr. A Dayanand Reddy - President, TAGMA India and R Sree Prakash - Vice president, TAGMA India amidst an august industry gathering.

In his Address, A Dayanand Reddy – President, TAGMA INDIA welcomed the Chief Guest, Guest of Honour, Keynote Speaker, all the speakers, delegates and sponsors and thanked all for their valuable presence and support in organizing the 2nd International Tooling Summit 2017. He said that the main objective of making the Summit an Annual Event is to enhance knowledge and stay connected with members and bring the industry closer.

He further stated that the Indian tooling industry is expected to grow further with government initiatives. Major OEMs in India are working on a plan for indigenisation of components getting into their main assemblies as per government guidelines. Policy reforms by government to make the procurement of tooling from indigenous sources will ensure growth in domestic production. Hence, to enhance the contribution of tool room industry to the growth and development of the Indian National Economy and to encourage members to be progressive, this two day conference on tooling industry is an excellent platform for industry experts to get together, and share their opinion with industry delegate. With the union budget presented last week for total transformation of India and the GDP growth of 6.5% this year and forecast of about 8% for the next year, with various pro industry policies of the Central Government including MAKE IN INDIA program, let's hope all of us are poised for good business in the immediate future and in the years to come.

He gave brief synopsis of the objectives of the association and various activities conducted by the Executive Council since 2014 like the 2 successful events ‘The International Tooling Summit 2016’, ‘10th Die & Mould India International Exhibition’, formation of chapters at Hyderabad, Bangalore, Mumbai, Gurugram and Noida to get connected with the industry and also to bring the members closer thereby helping them to work in cooperation. He announced the 3rd edition of the Summit will be held in Chennai on 1st and 2nd Feb. 2018.

He requested all to participate with full enthusiasm to derive maximum benefit from this event and take away some good technical inputs too.

President and Vice President TAGMA INDIA welcomed the diginitaries

Chief Guest Address

In his inaugural address Chief Guest of ITS 2017 Rajiv Gandhi said that the auto sector is facing challenges of fast changes in customer preference thereby leading to changes in product life cycle and also the concern for environment and safety norm that is front and side impact and pedestrian safety, due to the which the OEM has challenge of designing much stronger and at the same time lighter vehicles. To achieve this objective the tool manufacturers and OEMS should jointly work from design stage.

He further added that India is a country full of opportunities and is capable to unleash much more to the world. The manufacturing sector plays a significant role in India's GDP and for this sector to grow, the OEMs cannot do it all alone. The entire ecosystem has to work together. Also the emphasize should be on Speed to meet demand of OEM customers, Scaling the operations for being cost competitive and Skill to upgrade and keep pace with this ever changing technology. TAGMA’s role in this will be very crucial in providing platform wherein toolmakers and OEMs come and work together in different areas which will in turn lead to benefit of the OEMs and suppliers and create a win-win situation.

He thanked TAGMA Executive Council for inviting him to be part of the august gathering and for giving him an opportunity to share his thoughts. He also welcomed all delegates and wished them a fruitful association.

Guest of Honour Address by S K Arya

In his address S K ARYA said that Tooling as domain needs lot of skills like process, planning, design, analysis, problem solving, workmanship and strong technical fundamentals. Presently many tooling engineers are working with international design offices and are setting up their facilities in India thereby serving the requirement of global automotive and engineering industry.

During last few years major changes have taken place in metal forming dies and tools like -

- The light weight vehicles without compromising on the safety and structural strength has resulted into big change in the technologies involved in the tool manufacturing.

- Gradual prominence of transfer and progressive tooling by OEMs and allied industries to enhance productivity and to ensure quality with repeatability.

- Enhanced focus on advanced inspection online techniques to ascertain accuracy requirements thereby introduction of technologies like new age CMM and scanning for product certification.

- Use of IT has significantly increased in tooling with new software for platforms and advanced simulation technologies to predict tooling behavior in different processes and grades of steel.

The above changes has lead the Indian tooling industry to come at par with leading tooling stalwarts like German and Japan, only area in which improvement is required is sustained training and learning culture with determination and passion to become world class tooling.

With ever increasing fierce competition amongst OEMs to increase their market share various models and facelifts are launched by the industry leading to great opportunity to the tooling industry. Today’s challenge is to meet timely commitment and at an optimum cost with first time right components. He requested OEMs to place confidence in Indian tool manufacturing companies which will give momentum to the growth of Indian tooling industry and boost the endeavors of becoming the preferred choice in tooling’s.

He concluded that - It is rightly said that ‘You cannot do today’s job with yesterdays methods and be in business tomorrow’. He urged that all the tooling professionals should adopt the changes not only to survive but also to sustain and excel thereby making India the tooling hub of the world.

Keynote Address by Michael Walter

He thanked TAGMA for giving him an opportunity to present Keynote Address. He made special mention of PCK family for their hardwork and loyalty.

In his address he stated that the summit has set right tone beginning with the Automotive Sector followed by components and now steel producer, thus covering whole continent of very complex supply chain we are all in. During his tour to India he came across lot of technology, rising capacity, quality of product and process improving, together with spirit of changing innovation and quality. However, we need to strive for effectiveness into global competition to compete with international toolmaking in global supply chain. If the customers says that prices are too high you can reduce the price on the original margins and subsequently reduce short term costs, purchasing price, maintenance cost, without compromising quality and at the same time delivering on time. That’s how you find efficiency in long-term cost cutting.

He concluded by saying that we should have common understanding in the complexity of supply chain and combine our forces to able to increase the complex forms beside not losing our margins as at the end we all need to have profitable business.

Guest of Honour Address of Christen Merkle

Guest of Honour - Christen Merkle could not make it due to personal emergency hence. Mr. Gaurang Shah – Executive Council Member, TAGMA represented him. He introduced Christen Merkle and his company AHP Merkle the global leader in manufacturing of hydraulic cylinders. On behalf of the TAGMA EC Members he thanked Mr. Merkle for his spontaneous contribution of Rs. 50 Lacs and and further support for training vertical of TAGMA CET especially in hydraulics. He praised Mr. Merkle for his visionary support and belief in growth of Indian toolrooms industry towards self sufficiency in near future.

Vote of thanks by Mr. R Sree Prakash

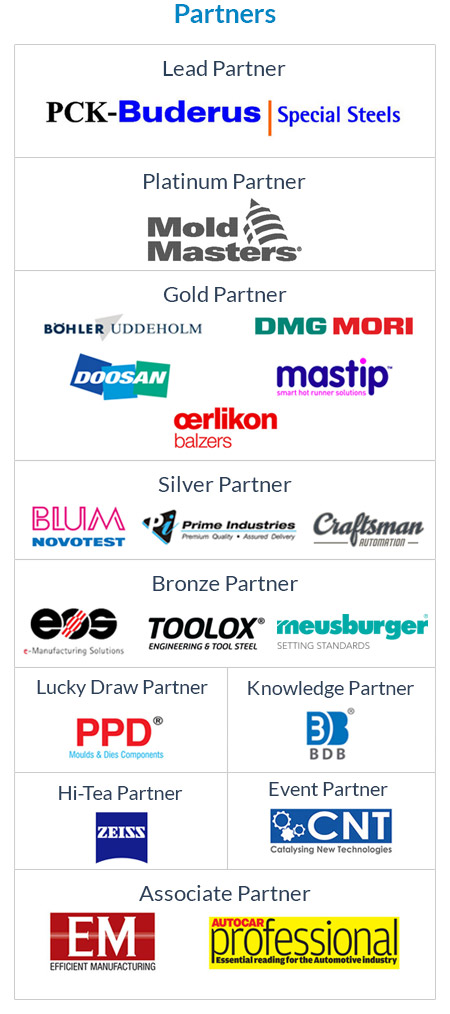

Mr. Sree Prakash mentioned that its always being great pleasure to meet up with industry friends. On behalf of TAGMA Executive Council he thanked Mr. Gandhi for sharing informative data, giving insight on huge requirement for quality tooling and assured that TAGMA will act as bridge between OEMs and toolrooms, Mr. Arya for sharing his views on importance of upgrading technology skill levels and making best use of opportunity, Mr. Walter for stressing for the need to get global understanding of all the units of supply chain and Mr. Christen Merkle for extending support in TAGMA activities. He also thanked all sponsors of the event for the support extended

Panel discussion 1 - ‘Indian tooling industry-quest for self-sufficiency and end user perspective’

The panel discussion threw up the importance of manufacturing quality tools and adhering to vehicle manufacturer timelines over and above costs. At present, about 63 percent of the toolings are used by the Indian automotive industry with other consuming sectors being FMCG and white goods. Sticking to timelines, maintaining right quality and consistency of tools is necessary to reduce dependence on imports since the white goods industry is currently importing almost 100 percent of their tooling requirements.

LtoR

Moderator: Mr Sumantra B Barooah - Associate Editor, AUTOCAR Professional

Mr. Rajeev Wasan - Senior VP, Manufacturing, Honda Cars India

Mr BB Gupta - President, JBM Group

Mr. AS Raju - Senior VP, Supply Chain, Maruti Suzuki

Mr BJ Wadia - Executive VP, Innovation and Technolgy, Godrej Appliances

Today due to rapid change in customer demands the life span of the product is short, hence there is huge opportunity for Tooling industry. The OEMs are focusing on localizing which helps in reducing cost, transit time, obvious scope for better interaction and coordination with the designers, however they expect the improvement by toolmakers. Reducing the lead time between tooling and vehicle production from the current 9-12 months was emphasized. Also need for quality maturity and focus on simulation improvement to reduce number of product trials and getting it right first time around. In addition, there is a need for increased involvement of the toolmaker and designer in engineering the component. Since vehicle upgrades and variants have become the order of the day, designing has to work concurrently with engineering and tool making. The ability of toolmakers to adhere to strict timelines of OEMs and not just look at costs but be able to manufacture tools accurately while maintaining good quality are necessary. The knowledge, training and experience is key to deliver appropriate tooling which can come if the toolmakers specialise in one particular industry as done by the toolmakers in China, Taiwan, Korea. Further the toolrooms should volunteer to manufacture the surrounding adjacent part to match the assembly part thereby saving time and should also focus on specialization in areas such as vacuum forming.

The tooling industry requires to focus on faster turnaround time, design competency, improved project management, specification adherence, high quality standards and safer work environment.

After panel discussion a number of global experts from tooling and gauging industry made technical session around the changing technology landscape in the industry.

“Tool Room Survey”

By Manish Kulkarni - Director – Strategy & Business Development, BDB India Private Limited

BDB is associated with TAGMA INDIA for last many years as Knowledge Partner. Since 2012 a comprehensive study conducted in 2011 subsequently periodical updates done since then BDB also works very closely with other associations

He gave a summary of the benefits of the study of Indian Tooling Industry and the methodology. He requested cooperation from the industry to BDB team when they are approached for the survey.

Technologies discussed on the first day were

"Make your factory smart with SmartMoldTM"

By Mr. Sunil Parol - Director - Technical, Milacron - Mold Masters

"Steel Solution for Efficient Mold Production - The DOOSAN Way"

Doosan | Mr. Bongkuk Choo - Material expert for Mold and Tool steel technology in Doosan

“Latest Trends in coating for improving performance of Forming tools”

Mr.Thomas Vermland - Forming Tools Appl. Manager New Technologies, BTMA / BU Balzers Industrial Solutions

"Trends and technologies in the manufacturing big molds"

Mr. Christofer Polz - General Manager - Forged Products, Buderus Edelstahl GmbH

"MASTIP - 25 years of experience adding value to customers"

Mr. Marc Michel - CEO, Mastip

“The AHP-Merkle-Strategy” What is the advantage of innovation or: Make it easy to decide for your customers by innovation

Mr. Abhinav Shah – Sr. Manager, North, Madhu Machine Systems presented on behalf of Mr. Christen Merkle – CEO, AHP Merkle

"Computer Tomography for Metrology and reverse Engineering"

Mr. S. N. Ravi Kumar - Vice President – Services, Carl Zeiss

The evening session kick started with GST Session by Mr. Abhay Desai, Chartered Accountant, Yagnesh Desai and Company gave a very informative and engaging presentation on Impact of GST on Tooling Industry.

He mentioned that the Indian tool makers are at cross roads. Just as China has gone from having a few dozen tool shop’s in 1960’s (mostly in Kowloon) to over 30,000 today aided by rapid rise in manufacturing, Indian tool makers with unique skill set and advanced technology can also expect a similar rise followed by rise in manufacturing due to ‘Make in India’. Further GST shall provide good impetus to the tool makers by way of reduction in cost. Currently Central Sales Tax (“CST”), Octroi & Service Tax is becoming a cost in the hands of tool makers. GST shall eliminate this distortion. GST shall also usher transparency in the economy and hence any advantage gained through avoiding the tax will no longer be available. GST coupled with “Skill India” & “Make in India” program’s have a potential to change the fortunes of this industry.

Presentation on 11th Die & Mould India International Exhibition

D K Sharma thanked all for motiviating TAGMA to create milestones like International Tooling Summit and Die & Mould India International Exhibition. He gave short presentation on the 11th edition of Die & Mould India International Exhibition to be held from 11th to 14th April 2018 at Bombay Exhibition Centre, Goregaon, Mumbai and requested large scale participation from the industry to showcase their capabilities.

Felicitation of senior leaders for their valuable contribution to the industry

TAGMA Centre of Excellence and Training [TAGMA CET]

Rohit Thawani gave presentation on TAGMA CET and appealed the industry to participate in the centre thereby contributing to the growth of the tooling industry

TAGMA CET at Chakan, Pune with an investment of Rs 50 crore, will enhance the competitiveness of the Indian capital goods sector and support toolmakers around Pune. The centre will house tooling machining services, tool try out and validation facilities. Focus on activities for stamping and moulding currently not available will be offered to small and medium enterprises here besides technical skill development and training.

In terms of funding, DHI is giving TAGMA a grant of Rs 26.27 crore that constitutes 80 percent of the machinery value, pegged at around Rs 32 crore. Rs 11 crore will be sourced from the bank as a term loan and the balance Rs 15 crore will be met through equity in which TAGMA would be holding a 51 percent stake. The remaining 50 percent will accrue from the industry.

TAGMA felicitated equity contributors of TAGMA CET

Mr. Gaurang Shah represented Mr. Christen Merkle

Mr. Ramakrishna Edara represented, Fibro

Uddeholm toolroom of the year award

Mr. Alok Jhamb from Bohler Uddeholm India made announcement of “Uddeholm Tool Room of the year award” sponsored by Uddeholm AB, Sweden. The first award will be presented at ITS 2018.

The cash prize of Euro 5000 which will be awarded by President Uddeholm during ITS 2018. The criteria will be decided jointly by the panel of which TAGMA will be a member, some of which will be :

- Award will be valid for commercial and captive toolrooms with sales turnover of less than 40 crores.

- Quality Management System which means the qlty norms followed by the company like UMS, TQM, 5s also.

- Other parameters like certification scheme, technology adoption, in-house facilities, kind of machine, the HR systems followed by company people competency.

We would also request Mr. D K Sharma and Mr. A Dayanand Reddy to be part of judgement committee.

He requested active participation of all toolrooms

He thanked Mr. Reddy on behalf of Uddeholm AB for giving the opportunity

The day ended with Cocktails and Networking Dinner

Day 2

In his opening remarks Mr. R Sree Prakash summarized the proceedings of day 1 that the cost is not primary motive its more due to quality and delivery aspect. It is left to tooling industry to figure out how we can partner with the OEMs and produce good quality tooling on time so that we get high productivity from the tools eventually at low price. There were lot of takeaways from the 7 technical session during the day. GST session was impressive which gave the insight on impact of GST on Tooling Industry

Panel discussion 2 - 3D Printing, 3D Scanning and Inspection for Tooling Industry

Investing in optimal conformal cooling is meaningful if there is high volume requirements. Also there should be knowledge of the whole technology before you implement it as the results can be best or worst. This technology not only reduces cycle time but gives less warpage and very high consistency in the process be it process parameters be it quality of product, consistency within the shot part, high cavity mold to part variations must be less and between the shots in the part variation will be less. It further saves 35% in the cycle times in some products and around 10-15% in every product however the user should weigh the advtg vis-à-vis the money invested.

LtoR

Moderator: Mr. Aditya Chadavarkar - Partner, Inside 3D Printing

Mr. Prakasam Anand - EOS - A Case Study of successful Implementation of 3D Printing

Mr. Nishant Shah - Imaginarium - A Service Bureau's Approach to 3D Printing

Mr. A. Dayanand Reddy - Vasantha Tool Crafts - User Perspective on 3D Printing for Conformal Cooling

Mr. Amar Kulkarni - Polyworks - 3D Scanning, Inspection and Reverse Engg

However there are challenges like its slow in operation, blockages of channels inside the core and the limitation of buying powder from the manufacturer only

The suppliers are trying innovate the machines which are predominantly plastic 3d printers, they are also working on different material like aluminium based plastic material

TAGMA CET

Mr. Vivek Nanivadekar handed over cheque of Rs. 25 lacs towards equity contribution of FIBRO India precision products Private Limited for TAGMA CET, Chakan, Pune

Panel discussion 3 - Collaborative effort towards enhanced tooling productivity

Moderator: Mr. DK Sharma - Executive VP & Business Head, Godrej Tooling

Mr. Anil S Patil - Business Head, Reliable Autotech Private Limited, Pune

Mr. Vivek Nanivadekar - Executive Director, FIBRO India precision products Private Limited

Mr. Elias Pinto - VP Tooling and Programe Management, Motherson Automotive Technologies and Engineering

Mr. Jean Louis - Vero Software, France

During Panel Discussion 1, OEMs discussed about their expectations from toolmakers and the areas that need to improvements. Toolmakers should operate in extreme efficient manner through out the manufacturing process thereby giving buyer the confidence that all the deliverables will be met. Productivity in tooling is not only restricted to tool making it is end to end solution which OEM expects to deliver alongwith time and quality. Early engagement of supplier partner EXPERTS for feasibility , cost proposals, a clear strategy like how to meet the customer aspiration, who will be the channel partners and how to work in collaboration with suppliers community is key to satisfy OEMs. Further, uunderstanding customers requirements will help in indigenisation - stock and sale also helps. Value added parts to be supplied by raw material suppliers make the life of toolmakers easy. I request everybody please see how you can give value added solutions to toolmakers. Scaling up is a challenge hence some delegates opined that TAGMA should negotiate better rates with some financial institutions which will benefit of tooling community

Technologies discussed on the second day were

“Modern trends in Machining”

Mr. Ravindra Krishnamurthy - Product Sales Manager, | DMG MORI

"Be Dynamic - efficient machining of Dies and Moulds"

Mr. Daniel Raravi - Director – Marketing & Strategic Initiatives | Mastercam India

"Surface Engineering of Tools through PVD Coating"

Dr. ECKART VOSS - Managing Director, EIFELER VACOTEC – GERMANY

FIBRO | Mr. Yann Curien - Chargé d'affaires PRONIC IN-DIE SOlUTIONS, France

"In-Die tapping solutions".

"Global perspective of EDM Technology and trends"

Mr. Stephen Harris - Global Product Manager - EDM, Tokai Carbon

"Optimizing the costing process in High Pressure Die-casting using MAGMA5 "

MAGMA Asia Pacific | Mr. Gerard Vong Yee Wen - Senior Foundry Application Manager, MAGMA Engineering Application Manager

"Current and Future trends in Sheet Metal Forming and Die Manufacturing Technology "

Mr Katsutoshi Suzuki - Technical advisor (Tooling) - JBM Group

"Blum Metrology Systems for Die & Mold Industry"

Mr B. V. Shyam - Managing Director, Blum Novotest India

Lucky Draw

Sponsored by Precision Punches and Dies [PPD]

Prize : Gold Coin of 50 gms

Criteria for delegates to qualify for Lucky draw

- Should have attended the conference on both the days

- Should have filled the feedback form completely for both the days

- Should be present in person during the lucky draw

Mr. Vipin Sharma – Yudo won the lucky draw at International Tooling Summit 2017. Dr. Sarita Parikh – NGO Supervasi and R Sree Prakash presented him the box containing Gold Coins of 50 gms.

By the Members, of the Members & for the Members

By the Members, of the Members & for the Members